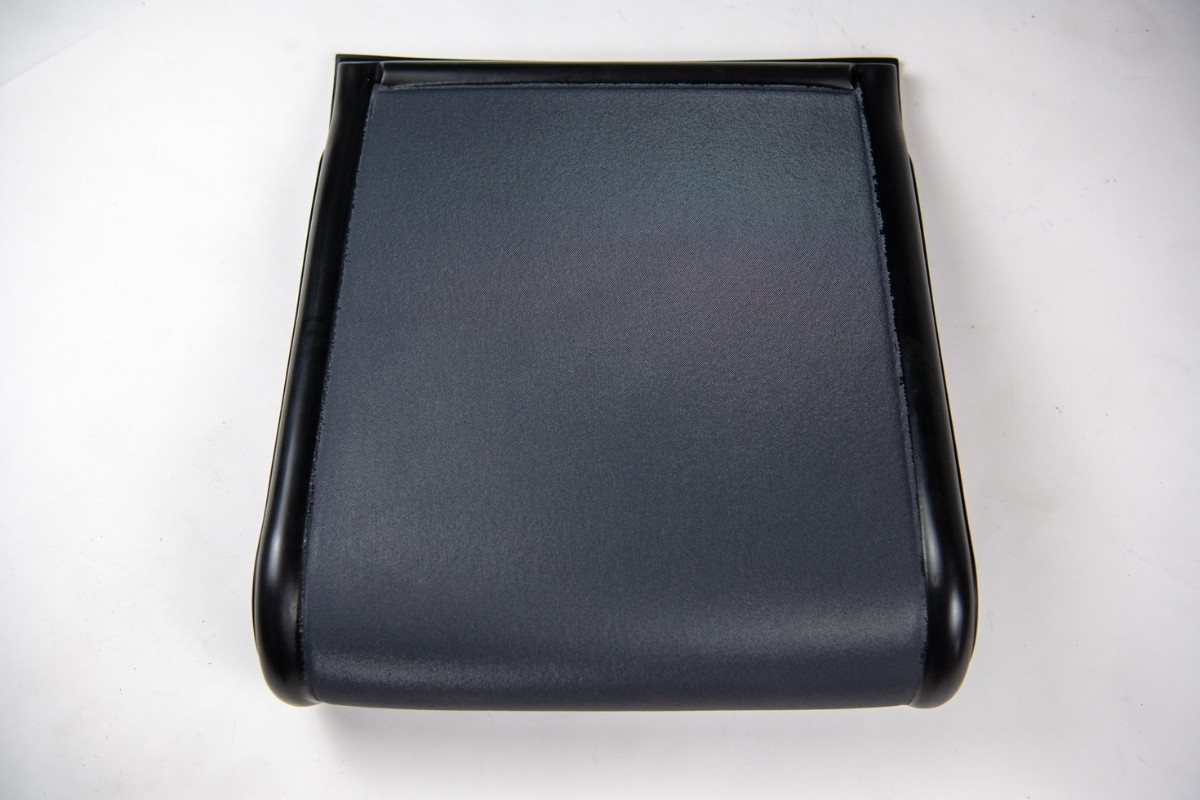

The semi-rigid integral skin urethane foam has a flexible and “rubbery” consistency which is suitable for the production of armrests, seats, steering wheels, but also gaskets, cavity filling elements, bumpers.

By acting on formulation and density, very different consistencies can be obtained.

This material has an expanded heart with semi-closed cells and a compact outer skin that is very resistant to abrasion; it can be printed in various colours and we are able to produce painted parts using in-mould coating technique.

With a photoengraved or sandblasted surface mould, it is possible to obtain very good surface finishes and. Like for rigid materials, it is possible to integrate metal inserts to give structure and create fixing points.